When a stepper motor transitions from one step to the next, the rotor does not settle instantly into its new position. Instead, due to its mechanical inertia and the spring-like magnetic forces between rotor and stator, the rotor overshoots the target step, then swings back in the opposite direction (undershoots), continuing to oscillate—or “ring”—before eventually stabilizing.

This ringing occurs with every step the motor takes. In normal operation, the motor is typically commanded to advance to the next step before these oscillations fully decay, which can influence positioning smoothness and accuracy.

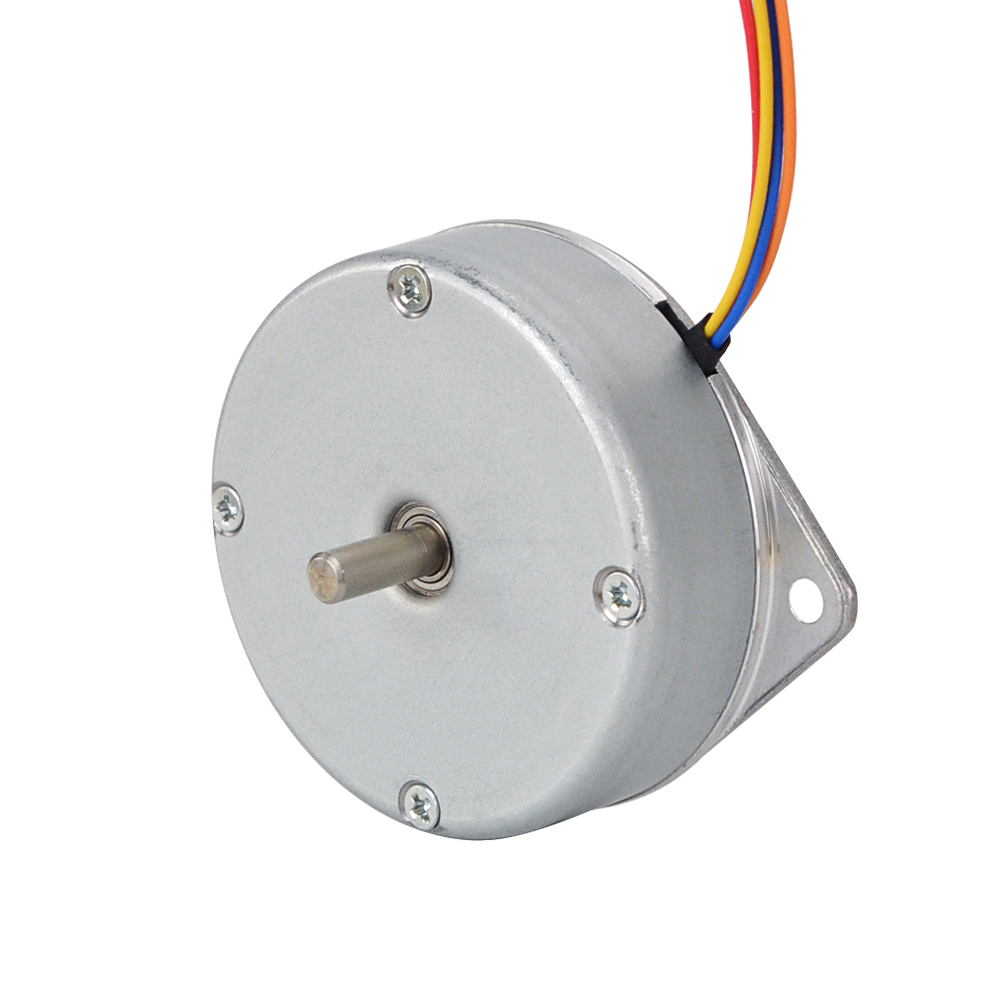

Under no-load or light-load conditions, ringing tends to be more pronounced, resulting in noticeable vibration. Excessive vibration can cause the motor to lose synchronism and stall, especially when the load torque is too low to provide adequate damping. To minimize vibration and ensure stable motion, the motor should be properly loaded. A suitable mechanical load typically requires 30–70% of the motor’s available torque, and the load inertia should be within 1:1 to 10:1 of the rotor inertia. For dynamic applications involving rapid starts and stops, a lower inertia ratio—closer to 1:1 or 3:1—is recommended to improve responsiveness and reduce settling time.

Ringing amplifies significantly when the step pulse frequency aligns with the motor’s natural mechanical frequency, a condition known as resonance. During resonance, oscillations grow in amplitude, overshoot and undershoot increase dramatically, and the risk of missed steps rises substantially. While the inertia of an attached load can provide some damping and slightly shift the resonant frequency, resonance generally remains a critical concern in stepper motor system design. Proper tuning of microstepping, drive current, mechanical coupling, or the use of inertial dampers can help mitigate these effects and ensure reliable performance across the operating speed range.

Troubleshooting Vibration and Resonance

A two-phase step motor can only miss steps in multiples of four full steps (equivalent to one tooth pitch or pole pitch). If the number of missing steps is a multiple of four, vibration or overloading may be causing a loss of synchronism. If the number of missing steps is not a multiple of four, an electronics problem is most likely the issue. There are a number of ways to get around resonance. The easiest way is to avoid the resonant speed range altogether. The resonant frequency for a two-phase motor is around 200pps; motors can be started at speeds above the resonant range. Accelerating quickly through the range is recommended if the motor must be started at a speed below the resonance range.

Half stepping and microstepping are also effective means of reducing vibration. Both methods reduce the size of each motor step. When the motor step angle is made smaller, the motor will vibrate less. The motor does not have to travel as far for each step, and less energy will be wasted in overshooting and undershooting. Step motors react differently to different loads. Make sure that the motor is sized properly to the load.