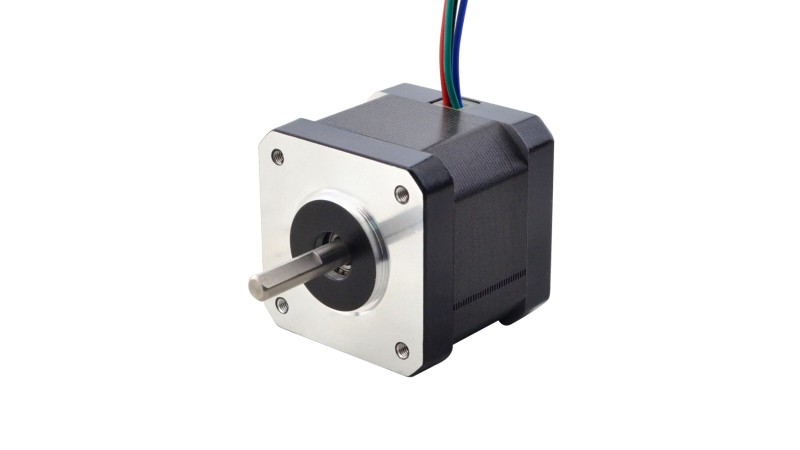

Stepper motors are primarily defined by their internal coil wiring. The two main configurations for 2-phase motors are unipolar and bipolar, each with distinct performance traits and drive requirements.

1. Core Difference: How Coils Are Wired

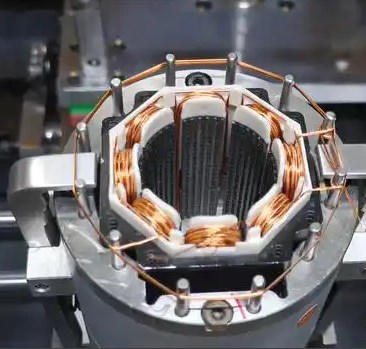

Unipolar motors utilize a center-tapped winding design for each phase, meaning each coil is divided into two symmetrical halves with a common midpoint connection. This configuration enables magnetic field reversal simply by switching the active coil segment—effectively alternating between the two halves—without needing to reverse current direction. As a result, the drive electronics can be simpler, often using fewer transistors per phase.

In contrast, bipolar motors feature a single continuous winding per phase without a center tap. To reverse the magnetic pole, the direction of current flowing through the entire winding must be reversed. This is typically accomplished using an H-bridge circuit—a more complex driver arrangement that allows current to flow in both directions through the coil. While requiring more sophisticated control, this design uses the full winding at all times, generally delivering higher torque and better coil utilization compared to unipolar configurations of similar size.

2. Torque & Speed Performance

Unipolar (Half-Coil): Lower inductance helps maintain torque at higher speeds, but reduces low-speed torque.

Bipolar Series: Uses full winding for strong low-speed torque, but torque drops faster at high speeds due to high inductance.

Bipolar Parallel: A flexible option offering balanced torque across speed ranges, though it requires higher current.

3. Motor Leads & Identification

Unipolar: Usually 5 or 6 leads. Resistance from common to coil-end is half of coil-end to coil-end.

Bipolar: 4 leads (2 per phase), no common connection.

8-Lead Universal: Can be wired as unipolar, bipolar series, or parallel for maximum flexibility.

4. Driving Circuits & Efficiency

Unipolar drives are simpler (often transistor-based) but less efficient, using only half the winding at once.

Bipolar drives need H-bridge circuits, yet modern driver chips simplify this. They use 100% of the winding, delivering more torque per size.

5. How to Choose

• Use unipolar for simplicity and low-cost projects.

• Choose bipolar for higher torque, efficiency, and modern applications.

• Consider 8-lead motors if you need to experiment with different wiring modes.

Summary: While unipolar motors are easier to drive, bipolar configurations—supported by today’s integrated drivers—offer better performance and are the go‑to choice for most precision motion systems.