Stepper motors and servo motors are both cornerstone technologies in industrial motion control, yet they operate on fundamentally different principles. Choosing the right one is not about which is "better," but which is **best suited for your specific application requirements**. This guide provides a detailed comparison across seven key dimensions to help you make an informed decision.

1. Fundamental Operating Principle

The core distinction lies in their control methodology:

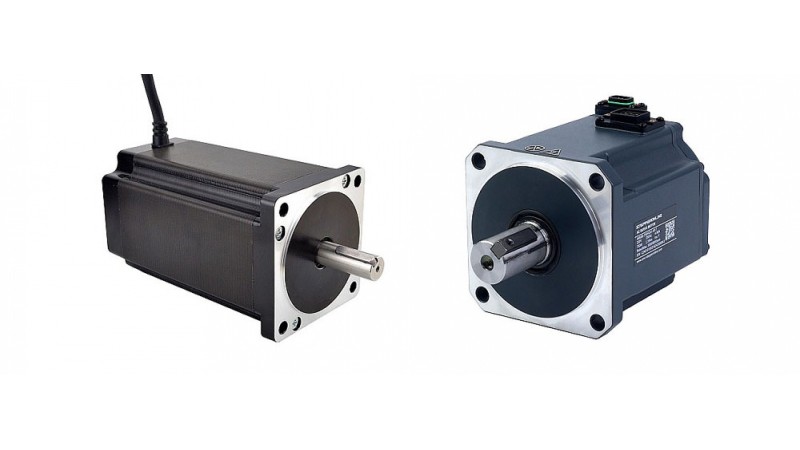

Stepper Motors operate in an open-loop system. They move in discrete steps (e.g., 1.8° or 0.9°) in response to electrical pulse signals from a driver. Each pulse commands a fixed rotation, and the motor's position is assumed based on the pulse count sent, with no verification.

Servo Motors function in a sophisticated closed-loop system. They incorporate a built-in encoder that constantly feeds real-time position data back to the controller. The controller compares this feedback with the target command and issues corrective signals. This continuous feedback loop allows for precise control of position, speed, and torque, and enables the system to compensate for disturbances or load changes dynamically.

2. Speed & Torque Performance

This is a critical area of differentiation impacting application suitability.

Stepper Motors excel at delivering very high holding and low-speed torque. However, their torque output decreases significantly as speed increases (see torque-speed curve). They can experience resonance and loss of torque at certain mid-range speeds, often requiring microstepping or mechanical damping to mitigate. Their maximum operational speed is generally lower (typically up to 1500-2000 RPM).

Servo Motors are designed for high-speed, high-performance applications. They deliver a consistent, constant torque across a much wider speed range, up to their rated speed (often 3000 RPM or higher). They also provide substantial overload torque (200-300% of rated torque) for short periods to handle peak demands, such as during acceleration.

Summary: Speed & Torque

Stepper Motor:

- a. Speed: Lower maximum speed (typically <2000 RPM).

- b. Torque Characteristic: High torque at low speeds; torque drops exponentially as speed rises.

- c. Best For: Applications requiring excellent low-speed torque and holding position without power (detent torque).

- d. Limitation: Not suitable for true torque-control applications or sustained high-speed operation.

Servo Motor:

- a. Speed: High maximum speed (commonly 3000-6000 RPM).

- b. Torque Characteristic: Constant rated torque across the entire speed range until the power limit is reached.

- c. Best For: High-speed applications, dynamic loads, and scenarios requiring peak overload capability.

- d. Versatility: Can operate in torque control, speed control, or position control modes.

3. Control Performance & Accuracy

Stepper Motors, being open-loop, are susceptible to missed steps if the load torque exceeds the motor's instantaneous torque, leading to positional errors that are uncorrected. However, within their operational limits, they provide good accuracy for many applications, especially with microstepping drivers that increase resolution.

Servo Motors provide superior accuracy and repeatability due to the closed-loop feedback. The system actively corrects for errors, preventing cumulative drift. This makes servos ideal for applications requiring high dynamic response, such as rapid start-stop cycles or following complex motion profiles.

4. System Cost & Complexity

Stepper Motor Systems have a significant cost advantage for simpler applications. The motor and driver are less expensive, and the open-loop setup requires no tuning, making it easier and faster to commission.

Servo Motor Systems are inherently more complex and higher in cost. This includes the cost of the motor with integrated encoder, a more sophisticated drive, and the need for system tuning (e.g., tuning PID loops) to achieve optimal performance. This complexity translates to higher performance and capability.

5. How to Choose: Application-Based Selection Guide

Use this decision framework based on your primary requirements:

Choose a Servo Motor if your application requires:

- High speed (> 800-1000 RPM) under load.

- High dynamic response and rapid acceleration/deceleration.

- Constant torque across a wide speed range.

- Overload capability for peak demands.

- Precise control of torque, speed, or position in a closed loop.

- Operation in environments with variable loads where missed steps cannot be tolerated.

Choose a Stepper Motor if your application has:

- Low to medium speed requirements.

- Constant, predictable loads well within the motor's torque curve.

- A need for simple, open-loop control with lower system cost.

- A primary requirement for holding torque when stationary.

- Less demanding dynamic performance needs.

6. Typical Industrial Applications

Servo Motor Applications (High Performance & Dynamic Control):

- Industrial Robots & CNC Machining Centers

- High-Speed Packaging, Pick-and-Place, and Assembly Machines

- Printing Presses and Web Tension Control

- Precision Test & Measurement Equipment

- Flight Simulators and Radar Antennas

Stepper Motor Applications (Precision Positioning & Cost-Effective Control):

- 3D Printers, Desktop CNC Routers, and Laser Cutters

- Medical Pumps, Analyzers, and Valve Control

- Textile Machines, Conveyor Indexing

- Document Scanners, Camera Auto-Focus (lens adjustment)

- Automated Stages in Optics and Semiconductor Handling

7. Direct Comparison Table

| # | Specification | Servo Motor (AC/Integrated) | Stepper Motor (Open/Closed Loop) |

|---|---|---|---|

| 1 | Control Type | Closed-Loop (with encoder feedback) | Typically Open-Loop (Closed-loop hybrids available) |

| 2 | System Cost | Higher (Motor, Drive, Tuning) | Lower & Cost-Effective |

| 3 | Speed Range | Very High (Rated 3000-6000 RPM) | Low to Medium (Max ~1500-2000 RPM) |

| 4 | Torque Profile | Constant Torque to rated speed; High overload | Decreases with speed; High at low speed |

| 5 | Control Modes | Position, Speed, Torque Control | Primarily Position (Step/Direction) |

| 6 | Accuracy | Defined by encoder resolution; Actively maintained | Function of step angle; Can lose steps |

| 7 | Complexity & Tuning | Higher; Requires commissioning & tuning | Simple; Often "plug and play" |

| 8 | Power Consumption | Draws current proportional to load; Efficient for dynamic tasks | Draws near-rated current always; Can be less efficient at partial load |

| 9 | Best Use Case | High-speed, high-dynamic, variable load applications | Low-speed, stable load, cost-sensitive positioning |

Technology Convergence Note: The line between these technologies is blurring. Modern closed-loop stepper systems (hybrids) add an encoder to provide positional feedback without missed steps, bridging the performance gap for many applications. Meanwhile, servo technology continues to become more accessible.

At STEPPERONLINE, we offer a comprehensive range of both high-performance servo motors and reliable, cost-effective stepper motors. Our experts can help you navigate this choice to find the optimal motion solution for your project's specific speed, torque, precision, and budget requirements.