The performance of a stepper motor is largely determined by its matching driver. The correct driver not only unlocks the motor's full potential but also ensures smooth, efficient, and reliable system operation. Here is a detailed step-by-step selection guide to help you find the optimal match.

Step 1: Identify the Basic Parameters of Your Motor and System

This is the foundation for selection. Be sure to confirm the following:

- Motor Rated Current: This is the most critical parameter. The driver's output current capability must cover the motor's rated current. The basic principle is: the driver's adjustable output current range should include the motor's rated current value. For example, if a motor has a rated current of 2.0A, the driver should be able to provide at least 2.0A of output.

- Motor Type (Open-Loop vs. Closed-Loop): This is the primary factor determining the driver category.

- Open-Loop Stepper Motors: The most common type, typically paired with open-loop drivers. Driver selection for these is relatively flexible, primarily based on the current matching principle mentioned above. On our product pages, compatible driver models are usually listed in the "Related Products" or "Recommended Accessories" column on the right side of the page.

- Closed-Loop Stepper Motors (e.g., Hybrid Servos): Equipped with built-in encoders for position feedback, these must be used with dedicated closed-loop stepper drivers. These drivers can monitor and compensate for lost steps in real-time, achieving higher precision and torque. On our platform, the selection of driver models suitable for closed-loop motors is more straightforward and can typically be directly filtered in product sections or dedicated categories.

- Power Supply Voltage: The driver's input voltage range must match your power supply. A higher supply voltage generally allows the motor to achieve better torque performance at high speeds.

Step 2: Understand Key Driver Performance and Features

Once basic compatibility is met, the following characteristics determine the fine performance of your system:

- Current Control Mode:

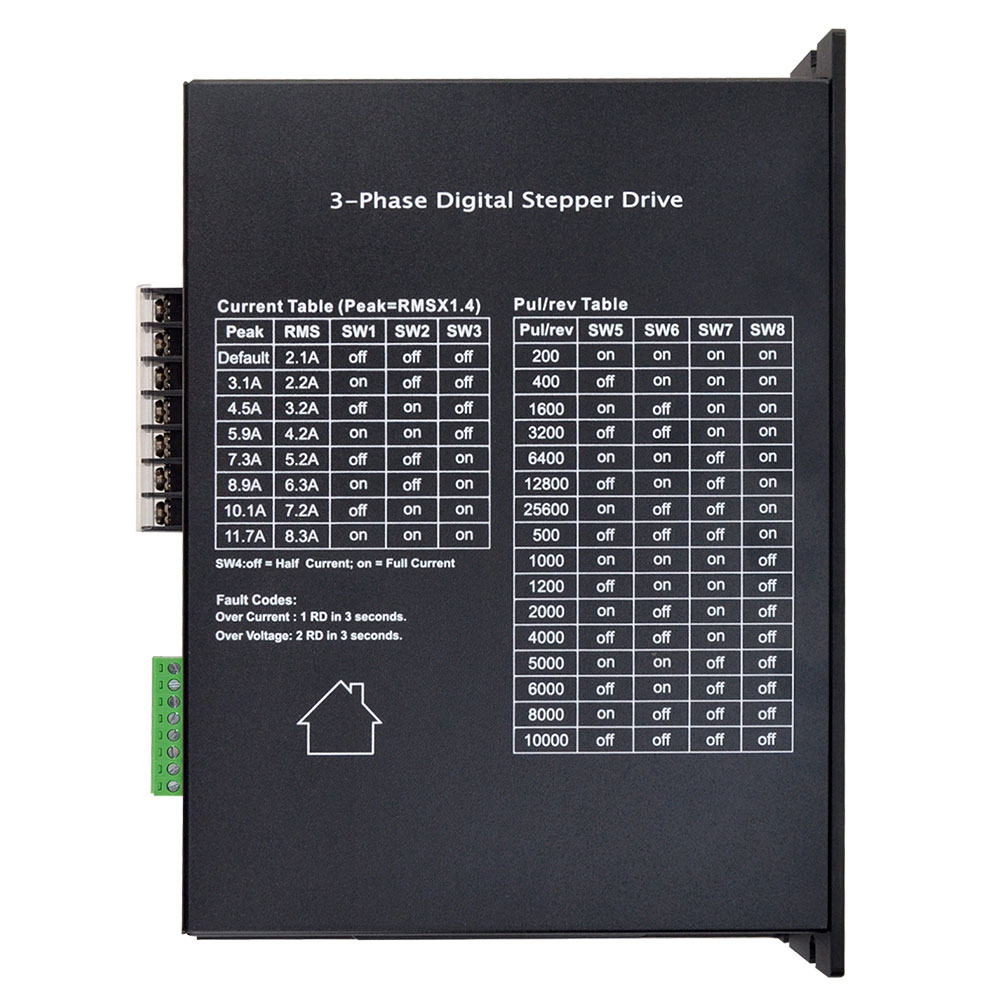

- Chopper Technology: Most modern drivers use PWM constant current chopper technology for precise current control.

- Microstepping: This is a core function. The driver divides one full motor step into multiple microsteps (e.g., 2, 4, 16, 256 microsteps), which can significantly improve running smoothness, reduce vibration and noise. For applications requiring low-speed smoothness or high-resolution positioning (e.g., 3D printing, precision instruments), a driver with high microstepping capability is ideal.

- Protection and Interface Features:

- Basic Protection: Ensure the driver has over-current, over-temperature, and short-circuit protection, which is crucial for system safety.

- Control Interface: The driver must support the signal interface of your main controller (e.g., PLC, Arduino, motion control card). Common interfaces include Pulse/Direction or CW/CCW (dual-pulse) signals.

- Enable and Alarm Outputs: The Enable (EN) signal can be used for power saving or motor locking, while the Alarm (ALM) output is useful for fault diagnosis.

Step 3: Select the Model Series Based on Your Specific Application

Our product line offers series optimized for different applications. Understanding their focus areas will help you make a better choice:

- Standard Economy Series: Meets basic positioning needs with high cost-effectiveness, suitable for general automation equipment where cost is sensitive and performance requirements are not extreme.

- High-Performance Microstepping Series: Offers high microstepping precision and smoothness, especially suitable for applications with high demands on motion quality, noise, and low-speed smoothness, such as high-end engraving machines, optical equipment, and laboratory instruments.

- High-Integration/Compact Series: Features a small form factor, sometimes integrating power supplies or control logic, suitable for space-constrained applications.

- Network Communication Series: Supports industrial buses like Modbus, CANopen, or EtherCAT, suitable for complex automation systems requiring multi-axis synchronization or remote configuration.

Summary and Recommended Process

- Check the Basics: Confirm the rated current and type (open-loop/closed-loop) from your motor's nameplate or datasheet.

- Initial Screening on Our Platform: Visit our official website. The quickest and most reliable method is to look for officially recommended matching drivers in the "Related Products" or "Compatible Accessories" column (usually located on the right side of the page) on the relevant motor product page.

- Refine Your Requirements: Based on your application's demands for motion smoothness, precision, and communication methods, select the appropriate microstepping level and functional series from drivers that meet the current matching criteria.

- Verify Power Supply and Interface: Finally, confirm that the driver's input voltage is compatible with your power system and that the control signal interface matches your main controller.

By following these steps, you will not only ensure the safe and stable operation of your motor and driver but also select the solution that best balances performance and cost for your project.