Selecting the appropriate motor for your application involves balancing multiple technical and practical considerations. Your choice will depend on factors such as cost constraints, required power output, operational lifespan, efficiency, and environmental conditions. Fortunately, NMB Tech offers a comprehensive range of motor types designed to meet diverse application needs—from low-cost, short-term solutions to high-performance, long-lasting systems.

For short-term projects or prototypes where budget is a primary concern, you may opt for a more economical motor, even if it entails a shorter service life. Conversely, in applications demanding extended operational life, high reliability, and consistent performance—such as medical devices, industrial automation, or aerospace systems—a Brushless DC (BLDC) motor is often the superior choice. As we will explore, the BLDC motor’s design offers distinct advantages in longevity, efficiency, and torque characteristics, making it a compelling investment despite a potentially higher initial cost.

Understanding Commutation: Brushed vs. Brushless

Commutation refers to the process of sequentially energizing motor windings to generate continuous rotational torque. In a brushed DC motor, this is achieved mechanically via carbon brushes contacting a rotating commutator, which inherently leads to wear, sparking, and electrical noise. In contrast, a BLDC motor employs electronic commutation, driven by a dedicated controller that activates windings in synchronization with the rotor's position—typically detected by Hall-effect sensors or back-EMF monitoring. This eliminates brush wear, reduces maintenance, and enhances operational smoothness.

Reliability & Cost Efficiency Over Time

One of the most significant advantages of BLDC motors is their extended service life, often exceeding 10,000 hours under rated conditions. The absence of brushes eliminates a primary failure mode, reducing downtime, maintenance costs, and replacement frequency. Although the upfront cost of a BLDC system (including motor and controller) may be higher than that of a brushed equivalent, the total cost of ownership is frequently lower due to reduced interruptions, higher energy efficiency, and longer operational lifespan—especially in continuous or demanding applications.

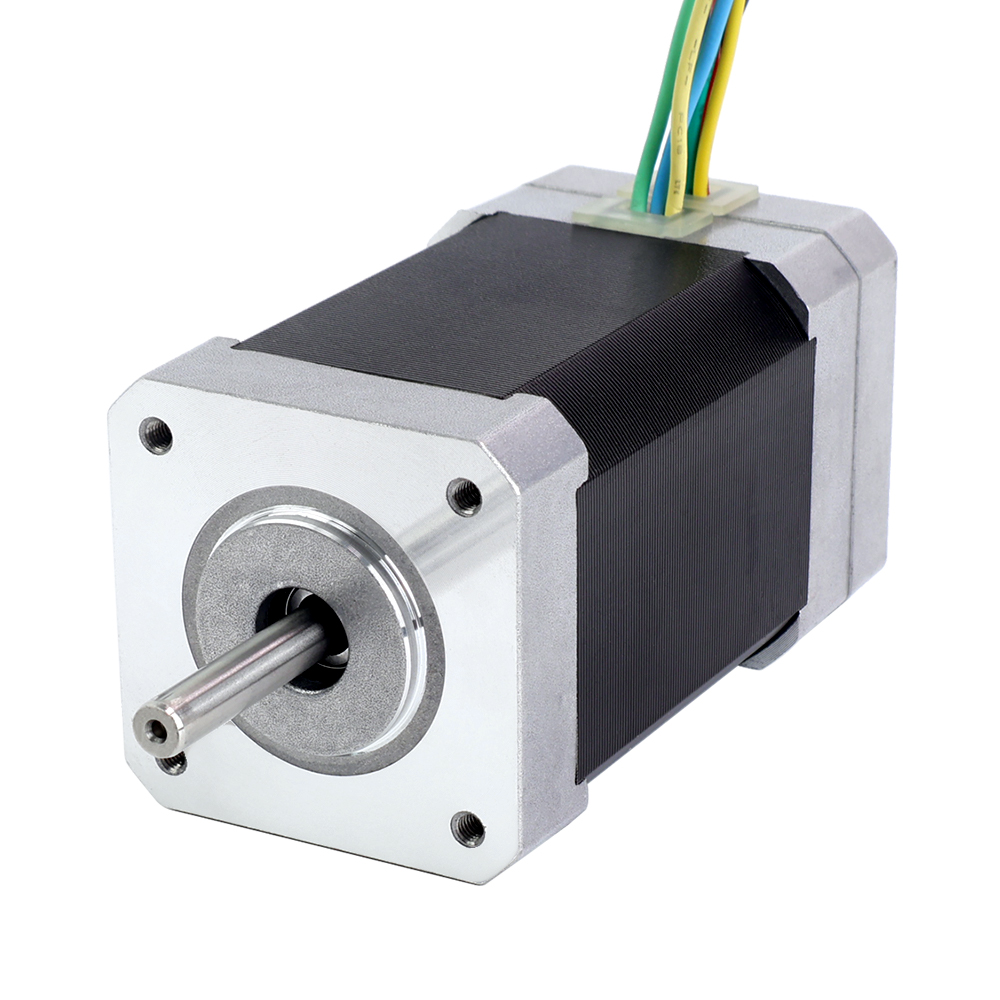

BLDC Motor Construction & Operating Principles

To fully appreciate the performance benefits of BLDC motors, it helps to understand their internal design and operation. All BLDC motors consist of two fundamental components:

- Stator: The stationary part, typically containing stacked steel laminations with wound copper coils.

- Rotor: The rotating part, which houses permanent magnets (often neodymium or samarium-cobalt).

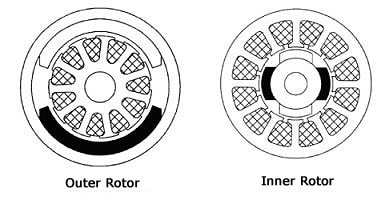

There are two primary mechanical configurations, each with distinct thermal and inertia characteristics:

Inner Rotor vs. Outer Rotor BLDC Motor Designs

1. Outer Rotor Design

In this configuration, the windings are situated in the motor’s core, surrounded by rotor magnets. The magnets act as a thermal insulator, which can limit heat dissipation. As a result, outer rotor motors often operate at lower duty cycles or reduced rated current. Their primary advantage is minimal cogging torque, making them suitable for applications requiring smooth low-speed rotation.

2. Inner Rotor Design

Here, the stator windings are mounted to the motor housing and encircle the rotor. This layout offers superior heat dissipation, allowing higher continuous torque output and better performance under load. The rotor’s smaller diameter also results in lower rotational inertia, enabling faster acceleration and deceleration. Consequently, inner rotor designs dominate in applications demanding high dynamic response and thermal efficiency.

Key Advantages of BLDC Motors

- High-Speed Capability: Can operate efficiently at speeds exceeding 10,000 RPM, both loaded and unloaded.

- Rapid Dynamic Response: Low rotor inertia (especially in inner rotor designs) enables quick acceleration, deceleration, and direction reversal.

- Exceptional Power Density: Delivers the highest continuous torque per unit volume among DC motor types.

- Long Service Life & Reliability: Brushless design eliminates wear-prone components, leading to lifespans often >10,000 hours and reduced maintenance.

- High Efficiency: Electronic commutation reduces resistive and friction losses, improving energy conversion especially in variable-speed applications.

- Quiet & Low-EMI Operation: Absence of brush arcing reduces electrical noise and audible vibration.

Summary: When selecting a motor, consider not only the initial cost but also long-term reliability, efficiency, and performance needs. For demanding, continuous, or high-speed applications, the BLDC motor’s advanced design, durability, and controllability make it an increasingly preferred choice in modern engineering systems.