You have some choices when it comes to determining which motor you will need for whatever application or project you are implementing, and your choice will depend on a variety of factors. Fortunately NMB Tech has a wide variety of motor types to fit a wide range of motor needs. Some of the issues you will need to consider for your motor are cost, amount of power you will need and how long you need your motor to last. If you have a project or application where you will only need a motor for short term use, you may prefer a cheaper motor that may wear out more quickly. If your job requires a motor that will last as long as possible, you will probably want to consider a BLDC motor, for reasons which will become apparent.

The Brushless DC (BLDC) motor is the ideal choice for applications that require high reliability, high efficiency, and high power-to-volume ratio. Generally speaking, a BLDC motor is considered to be a high performance motor that is capable of providing large amounts of torque over a vast speed range. BLDC motors are a derivative of the most commonly used DC motor, the brushed DC motor, and they share the same torque and speed performance curve characteristics. The major difference between BLDC and brushed DC motors is the use of brushes. BLDC motors do not have brushes ( hence the name "brushless DC") and must be electronically commutated.

Commutation is the act of changing the motor phase currents at the appropriate times to produce rotational torque. In a brush DC motor, the motor assembly contains a physical commutator which is moved by means of actual brushes in order to move the rotor. With a BLDC motor, electrical current powers a permanent magnet that causes the motor to move, so no physical commutator is necessary.

A BLDC motor is highly reliable since it does not have any brushes to wear out and replace. When operated in rated conditions, the life expectancy of a BLDC motor is over 10,000 hours. For long term applications, this can be a tremendous benefit. Whenever a motor breaks down or needs to be replaced, your project, or part of it, must be shut down. This costs you time and money, perhaps a great deal depending on how long it takes to replace the worn motor part or parts and get the application started again. Although a BLDC motor may cost more than a brushless motor, it will often more than pay for itself in the amount of work time saved.

BLDC Motor Construction and Operating Theory

To understand why a BLDC motor is so effective, it's important to have a good understanding of how it works. There are actually two different types of BLDC motors, with different benefits and drawbacks. While either one will probably be effective for most jobs, you may wish to familiarize yourself with both types, just in case one would be more appropriate for your project or application than the other.

Any BLDC motor has two primary parts; the rotor, the rotating part, and the stator, the stationary part. Other important parts of the motor are the stator windings and the rotor magnets.

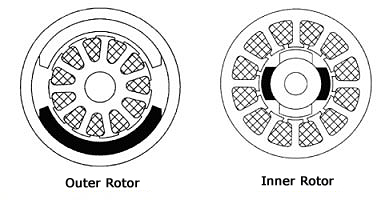

There are two basic BLDC motor designs: inner rotor and outer rotor design.

In an inner rotor design, the stator windings surround the rotor and are affixed to the motor's housing as shown here. The primary advantage of an inner rotor construction is its ability to dissipate heat. A motor’s ability to dissipate heat directly impacts its ability to produce torque. For this reason, the overwhelming majority of BLDC motors use an inner rotor design. Another advantage of an inner rotor BLDC motor is lower rotor inertia.

BLDC Motor Advantages:

If you're still not sure whether or not this motor is right for you, here is a basic breakdown of some of the primary advantages of the BLDC motor.

* High Speed Operation – A BLDC motor can operate at speeds above 10,000 rpm under loaded and unloaded conditions.

* Responsiveness & Quick Acceleration – Inner rotor Brushless DC motors have low rotor inertia, allowing them to accelerate, decelerate, and reverse direction quickly.

* High Power Density – BLDC motors have the highest running torque per cubic inch of any DC motor.

* High Reliability - BLDC motors do not have brushes, meaning they are more reliable and have life expectancies of over 10,000 hours. This results in fewer instances of replacement or repair and less overall down time for your project.

Subscribe our NewsletterSubscribe to get lastest news for products and special offers!

Established in 1992, OSM Technology Co.,Ltd. began as a consulting company specializing in Stepper motor applications. Throughout its history, OSMTEC has continued to develop its capabilities in the areas of design engineering, manufacturing, and customer service. In 1995, OSMTEC expanded its operatings to include the manufacturing of its own Hybrid Stepper Motor. Since then, the company has developed its product line to include Linear Actuator and Brushless DC Motor.

Our operations are certified to ISO 9001:2000 and QS 9000. All products carry major approvals such as CE and ROSH. With OSMTEC Technology, you get the highest quality products, all made possible by the most dedicated people.

CONTACT

Email: [email protected]

Phone: (+86)574 28837284

Adress: No. 535, Renmin Road, Jiangbei District Ningbo CN 315000

15-4, #799 Hushan Rd., Jiangning District, Nanjing CN, 211100

Powered By OSMTEC © 2023

CART

CART